Are you ready to dive into the world of circuit board assembly for industrial equipment? Whether you’re a seasoned professional or just starting on your journey, this comprehensive guide will provide you with valuable insights, tips, and suggestions to help you excel in this critical aspect of the manufacturing process.

Understanding the Importance of PCB Assembly

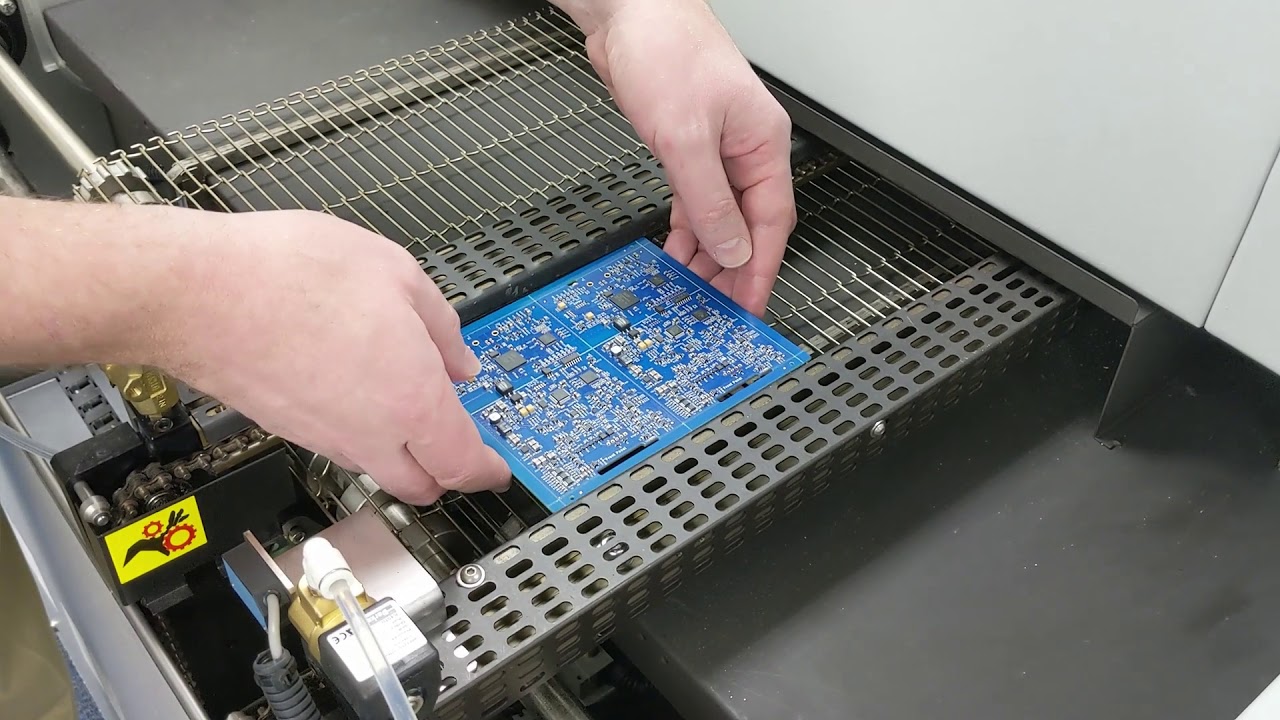

Circuit board assembly, also known as PCB assembly, is a fundamental component of industrial equipment manufacturing. These intricate boards serve as the brain of machinery, controlling its various functions and ensuring seamless operation. From manufacturing robots to CNC machines, from conveyor systems to automated packaging lines, virtually every industrial device relies on a well-assembled PCB.

Key Considerations for Circuit Board Assembly

- Component Selection: The first step in successful PCB assembly is choosing the right components. Opt for high-quality components that are compatible with your equipment’s specifications. Don’t cut corners here, as the performance and reliability of your industrial equipment depend on it.

- Design Optimization: Efficient circuit board design is crucial to minimize the risk of errors during assembly. Ensure that your board layout is clean, well-organized, and follows industry standards. Consider factors like trace routing, component placement, and signal integrity.

- Soldering Techniques: Mastering soldering techniques is essential for a flawless assembly. Whether you’re using surface mount technology (SMT) or through-hole components, make sure to use the appropriate soldering methods and equipment. Precision and consistency are key.

- Quality Control: Implement a robust quality control process to catch any defects or errors early in the assembly process. Automated optical inspection (AOI) and in-circuit testing (ICT) are valuable tools for identifying issues.

- ESD Protection: Electrostatic discharge (ESD) can wreak havoc on sensitive electronic components. Ensure that your assembly environment is ESD-protected with proper grounding, wrist straps, and static-safe workstations.

- Documentation: Maintain comprehensive documentation throughout the assembly process. Detailed records of components used, soldering profiles, and testing results will be invaluable for troubleshooting and future reference.

Circuit board assembly for industrial equipment is a critical skill that can make or break the performance of your machinery. By paying close attention to component selection, design optimization, soldering techniques, and quality control, you can ensure that your PCB assemblies are reliable and robust. Keep learning, collaborating, and improving, and you’ll become a master in this essential aspect of industrial equipment manufacturing.

Remember, the success of your industrial equipment relies on the quality of its circuit board assembly. So, invest the time and effort to get it right, and your machines will thank you with years of dependable service.